Printer-friendly version

Printer-friendly version Jar mills VM-200M and VM-500M are developed for grinding of different materials while continuous or periodic running. As grinding material can be used ore minerals, building materials, paints, oxides, refractory materials, mixtures etc. Jar mills VM-200M and VM-500M are service-strong and easy for use. It works without failing and breaking. All spare parts and consumable materials to realize service are standart products (drum support bearing, cups, support springs etc.

Jar mills VM-200M and VM-500M are developed for grinding of different materials while continuous or periodic running. As grinding material can be used ore minerals, building materials, paints, oxides, refractory materials, mixtures etc. Jar mills VM-200M and VM-500M are service-strong and easy for use. It works without failing and breaking. All spare parts and consumable materials to realize service are standart products (drum support bearing, cups, support springs etc.

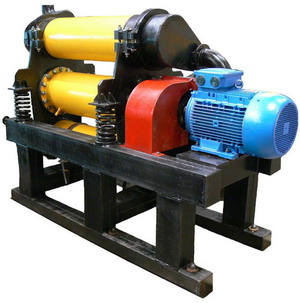

Jar mill VM-200M consists of two milling drums which are horizontally placed one under another. There is a vibration exciter with water-cooling jacket. Milling drums and vibration exciter are fixed on two slabs which are located on four flexible supports. The operating mechanism from the motor to the vibration exciter is introduced by elastic coupling. Motor base is fixed to the frame with four pins, which provide the device alignment of the motor and vibration exciter. Each milling drum has drum heads, fixed with through pins and connection clips. Nozzles are fixed to the drum heads, to load and unload the material.

Jar mill VM-500M is produced for grinding of different materials while continuous or periodic running. As grinding material can be used ore minerals, building materials, paints, oxides, refractory materials, mixtures etc.

Jar mill VM-500M is produced for grinding of different materials while continuous or periodic running. As grinding material can be used ore minerals, building materials, paints, oxides, refractory materials, mixtures etc.

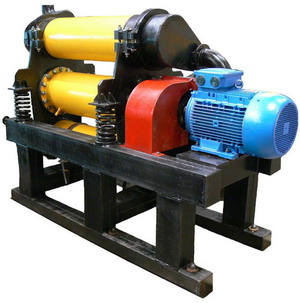

Jar mill VM-500M consists of three heavily fastened grinding drums. There is a vibration exciter with water-cooling jacket under the drums. Grinding drums are located on eight flexible supports. The operating mechanism from the motor to the vibration exciter is introduced by elastic coupling. Motor base is fixed to the frame with four pins, which provide the device alignment of the motor and vibration exciter. Each milling drum has a drum head, fixed with through pins and connection clips.

Specification sheet of the jar mills VM-200M and VM-500M

| Parameter |

VM-200M |

VM-500M |

| Number of grinding chambers, units |

2 |

3 |

| Grinding chamber capacity, dm3 |

100 |

170 |

| Charging feed size max, mm |

| Core grinding |

20 |

20 |

| Fine grinding |

5,0 |

5,0 |

| Combined grinding |

20 |

20 |

| Cooling water consumption, min, l/h |

100 |

200 |

| Weight of charging bodies in the drum, kg |

| Cores |

400 |

700 |

| Balls |

300 |

500 |

| Cycles per second, Hz |

24 |

24 |

| Installed capacity, kW |

22 |

55 |

| Overall size, mm |

| length |

2510 |

2660 |

| width |

880 |

1300 |

| height |

1750 |

1450 |

| Net weight, kg |

2100 |

3300 |

| Product fraction, mm |

0-0,5 |

0-0,1 |

| Productivity, t/h |

0,4-1,5 |

0,8-2,0 |

Jar mills VM-200M and VM-500M can be operated in three regimes:

-

Core grinding. As grinding bodies are used metal cores with diameter of 25-50 mm. Charging feed size should be not more than 20 mm.

-

Fine grinding. As grinding bodies are used grinding balls or other similar grinding bodies (i. g. rollers, iron grinding bodies etc.) with diameter of 15-30 mm. The size of the feedstock shall not be up to 5 mm. Size of the grinded product is smaller than 0.1-0.3 mm., depending on the material.

-

Combined grinding. As grinding bodies are used. In the upper drum - metal cores with diameter of 25-50 mm. In the lower drum – balls or similar bodies with diameter of 15-30 mm. Charging feed size should be not more than 20 mm.